In response to a call from a major Norwegian Oil & Gas operator, IK Subsea is now kicking-off a project to deliver a new tooling solution to the client. The challenge is to successfully clamp and plug a large flexible riser, 600m of which is connected between a subsea flange and a surface loading buoy. The asset is being decommissioned, and contains a % of oil and contaminants which must be sealed-off from the environment during the decommissioning activities. The project will run in Spring/ Summer 2023.

IK Subsea ran a comparative study here in their Norway facilities, investigating the forces and solutions needed to be able to clamp and seal such a large diameter flexible pipe. The study shows promising results, and a solution was drafted up and accepted by the client. This is a nice reminder of the value of running these preliminary studies with clients and how that can evolve into a deliverable for IK Subsea.

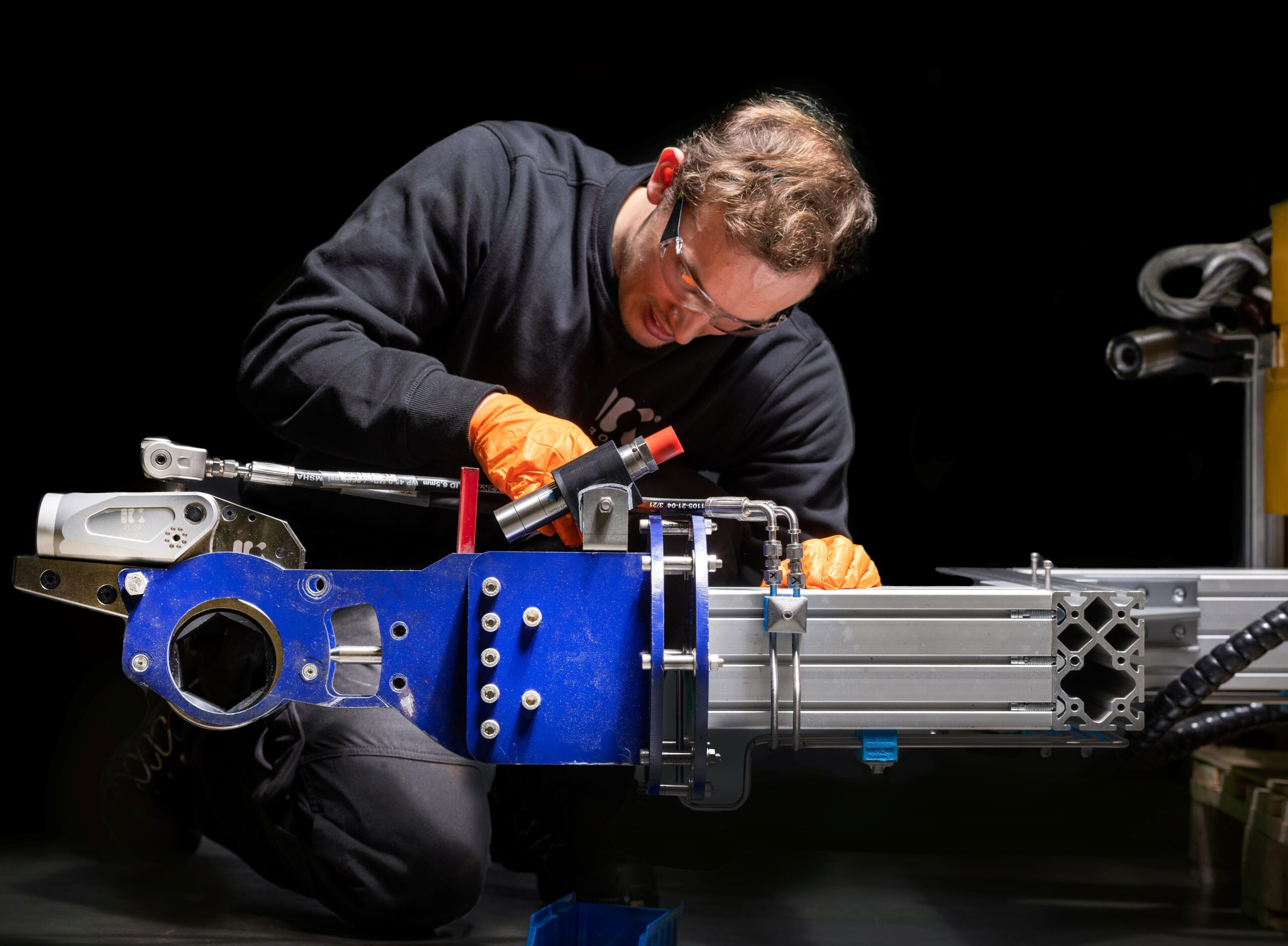

Project Manager, Huw Scott said, “The tool will be ROV operated as a 2-part solution, guided into position by a stabilisation clamp so that good alignment is maintained, whereupon the clamping tool will then be steadily closed using ROV torque tools. The solution appears simple at first, but we remain open minded to potential challenges as this solution is new and innovative. As we say: challenge accepted.”